Description

Carbon dioxide, when dissolving in the condensate, causes the formation of a weak carbonic acid, which causes a drop in pH level of the condensate, to even around pH=4.5. Under such circumstances, the condensate has highly corrosive qualities for carbon steel, which is the usual material for that return condensate to the boiler. This causes major losses due to damages caused by the corrosion, or discharging the condensate to wastewater.

For this reason, binding the free carbon dioxide is key to a safe and economic boiler exploitation. The usual solution to this issue are neutralizing amines, which bind to carbon dioxide and raise its pH.

Alternatively, filming preparations can be applied, creating a physical barier between the aggressive condensate and the metal surface. These preparations can also frequently be used for so-called wet preservation during downtime. The exact technology used is also chosen based on the technological process in which steam is applied (for example neutralizing amines can not be used when the steam has direct contact with milk or dairy products).

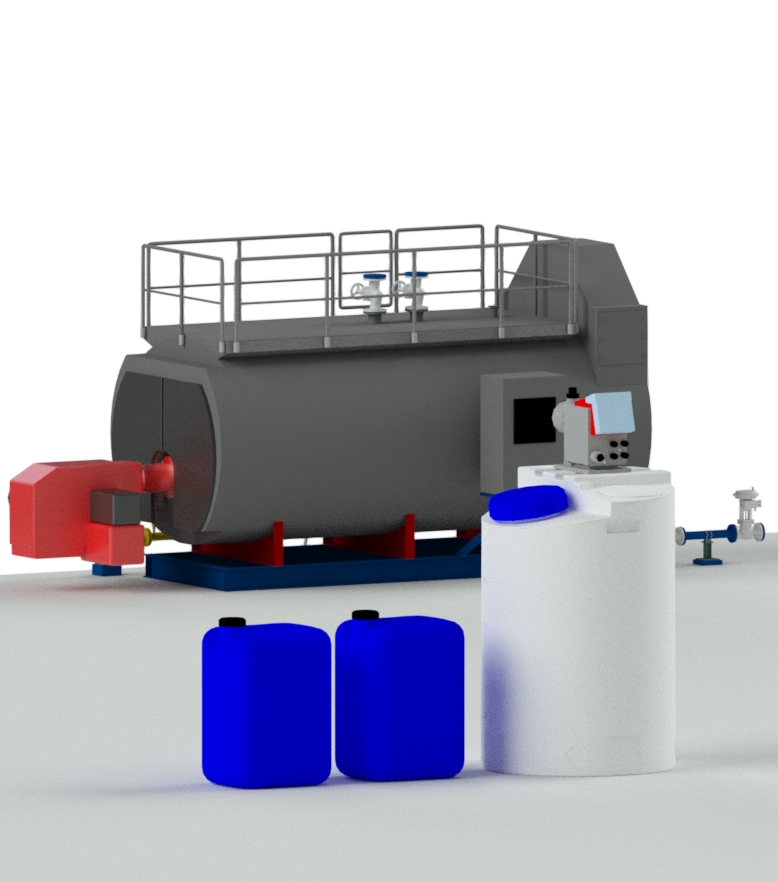

MCC offers selection and supply of preparations used to preserve boilers, as well as specialized dosage systems.