Description

All materials are subject to corrosive processes. They cannot be prevented, although their speed can be limited, ensuring economical usage of the system throughout its exploitation time. For carbon steel elements, the acceptable rate of corrosion is under 0.1mm/year. For copper and its alloys, the acceptable rat eis under 0.025mm/year. These quantities refer to the overall corrosion, under the assumption that it occurs at the same rate for the entire metal surface.

In the case of pitting corrosion, the average speed of corrosion might be in range, while there is significant damage to devices such as heat exchange units. Thus, preventing both pitting and general corrosion is necessary. It is important to remember that, corrosion occuring under residue collected on a metal surface is usually pitting.

Corrosion is accelerated by factors such as increased temperature, low water pH, the presence of strong oxidizers (such as high chlorine doses), or some microorganisms. Counteracting the corrosion process is usually part of a whole chemical program. Various corrosion inhibitors are used, including phosphorus compounds, zinc salts, molybdenum salts, triazole derivatives and others.

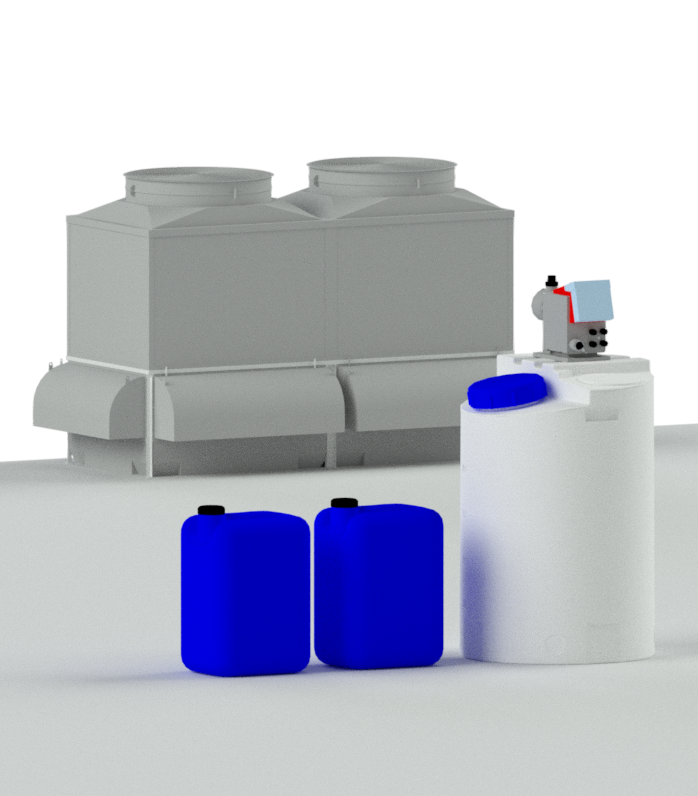

MCC offers selection and supply of the optimal chemical technology, as well as dosage systems and measurement systems to control the physicochemical parameters of water. We also offer specialized analytical services.