Description

In the case of large, industrial boiler rooms, the use of thermal or vacuum degassers, allows to reduce the oxygen concentration under 20ppb. In the case of smaller boiler rooms, it might be more economical to use chemical deoxidation.

The most popular deoxidant is sodium sulfurate, which needs to be catalized due to its quick reaction time. A fault of this prepration is it limits the pressure used in the system to about 60 bar. Another popular deoxidant is carbohydrazide. Additionally, some deoxidants have additional passivating qualities, which provide steel a level of corrosion resistance even in case of lack of deoxidant.

To select the apropriate technology, it is necessary to consider the structure of the system and technological aspects, such as the method of steam usage (select deoxidants must not make contact with food products).

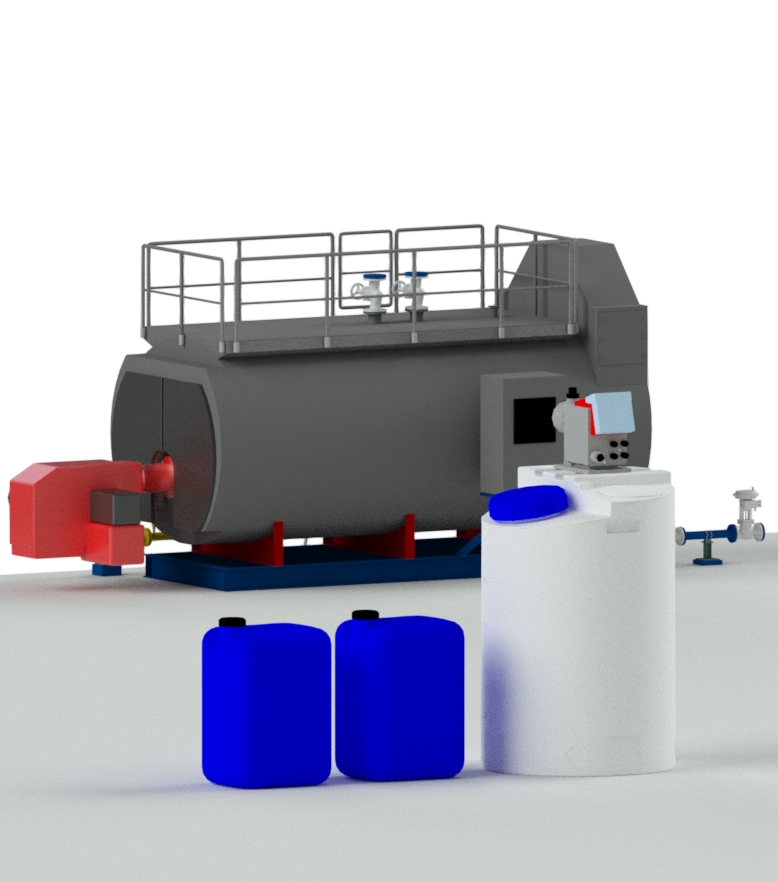

MCC offers both the selection and supply of preparations used to preserve boilers, as well as specialized dosage systems.