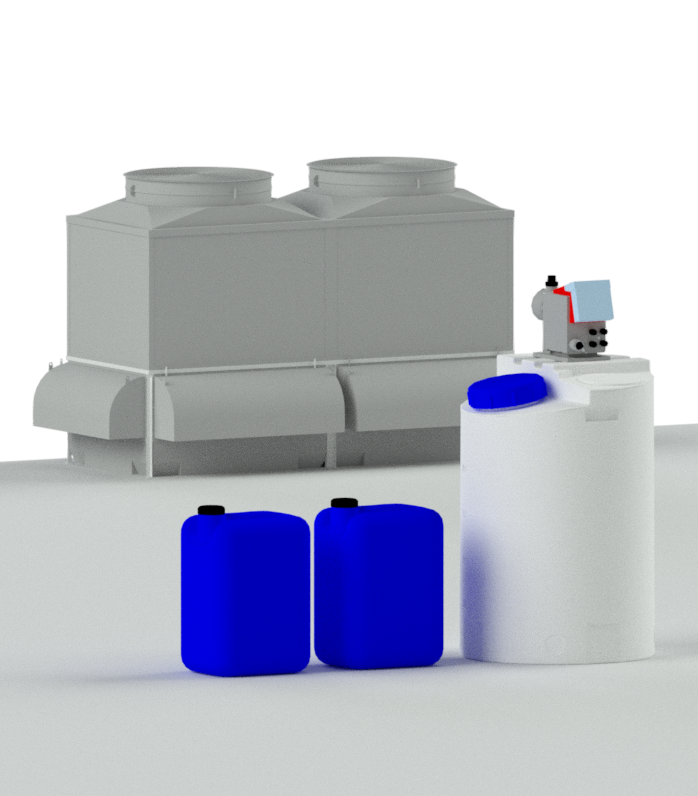

Description

During the process of ventilative cooling, the cooling water has constant contact with the surrounding air, and collects impurities, including organic particles (leaves, pollen) and inorganic particles such as sand. The same system is also subject to corrosive and sedimentary processes, and their products, such as iron oxides or chemical residue can form sediments.

The presence of said sediments causes the following negative effects:

* Restricting heat exchange and worsening the work economy of the system

* Occurence of undersedimental corrosion

* Creation of an environment for microorganism growth

All these phenomena lead to increased exploitation costs. To prevent them, specialized chemical preparations are used, which on one hand prevent the formation of chemical residue (antiscalants) and on the other, prevent the accumulation of slime in spaces with limited water flow (dispersants). The main ingredients of such preparations are, at the current moment, various organic compounds of phosphor, and organic polymers. The choice of preparation is based on the contents of the water supplying the system and other technical parameters, such as the operating temperaturę, stop time of water in the system and others.

MCC offers the selection and supply of a complex chemical regiment, along with tools for automatic dosage of preparations and measurement of the physicochemical parameters of the system.