Description

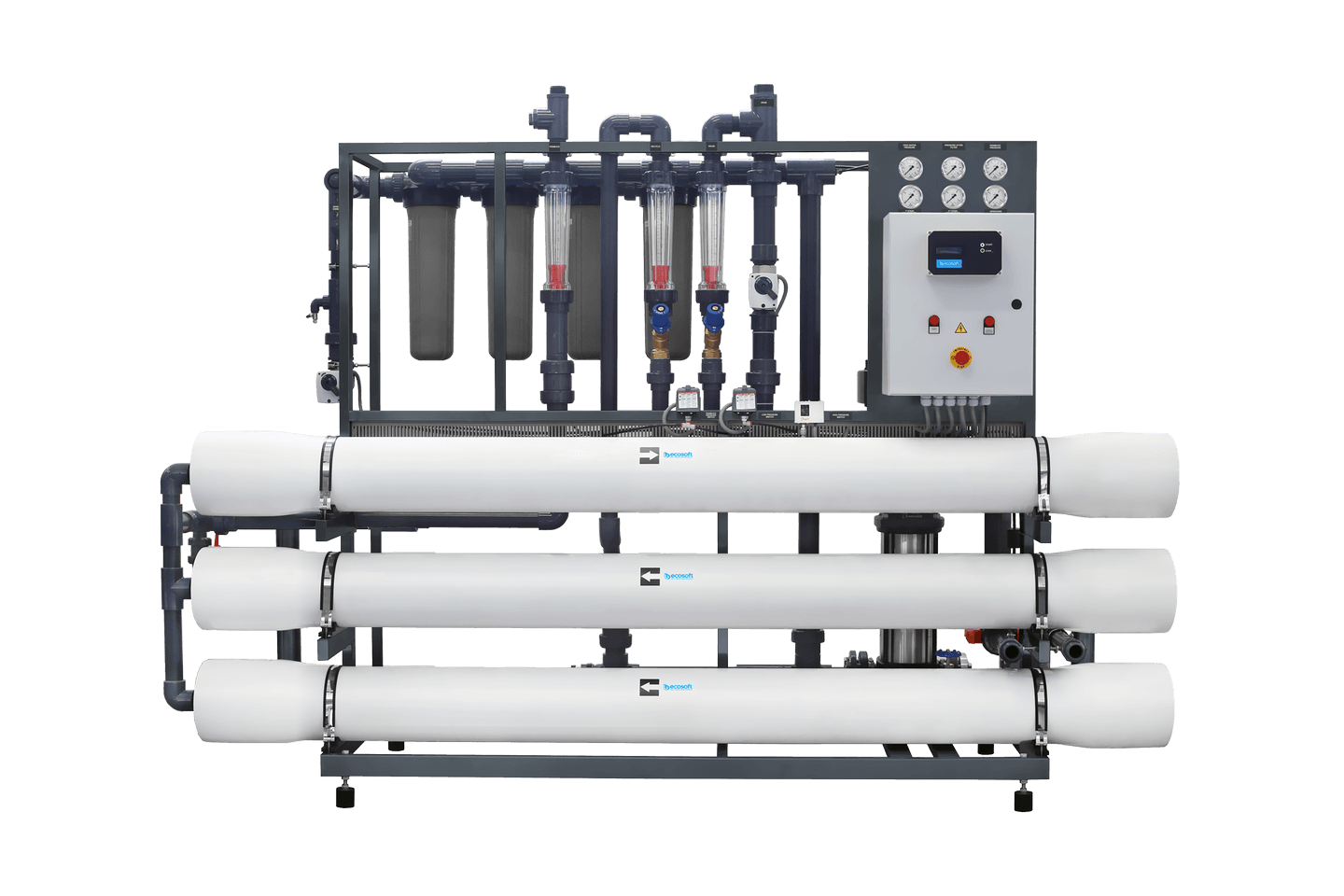

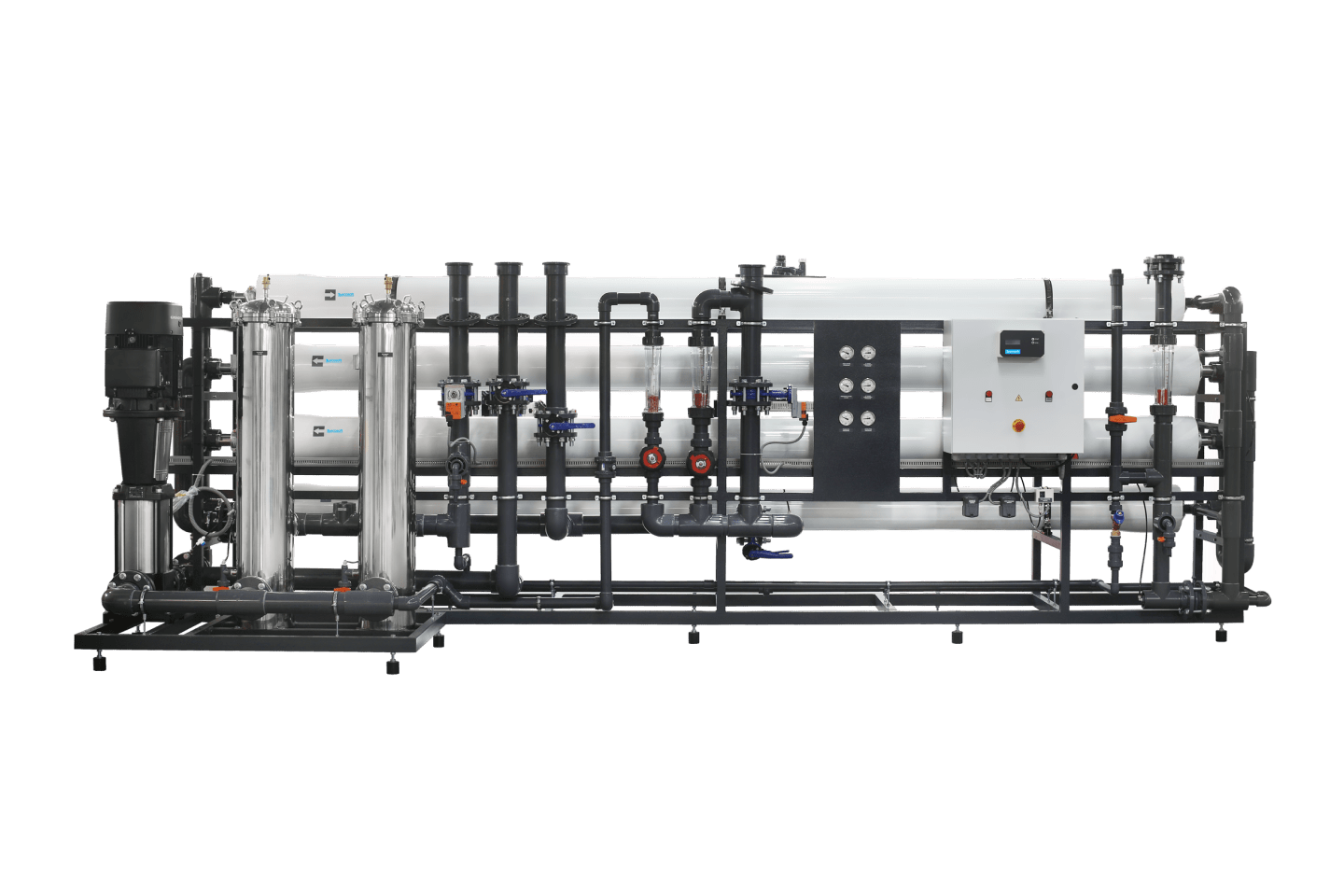

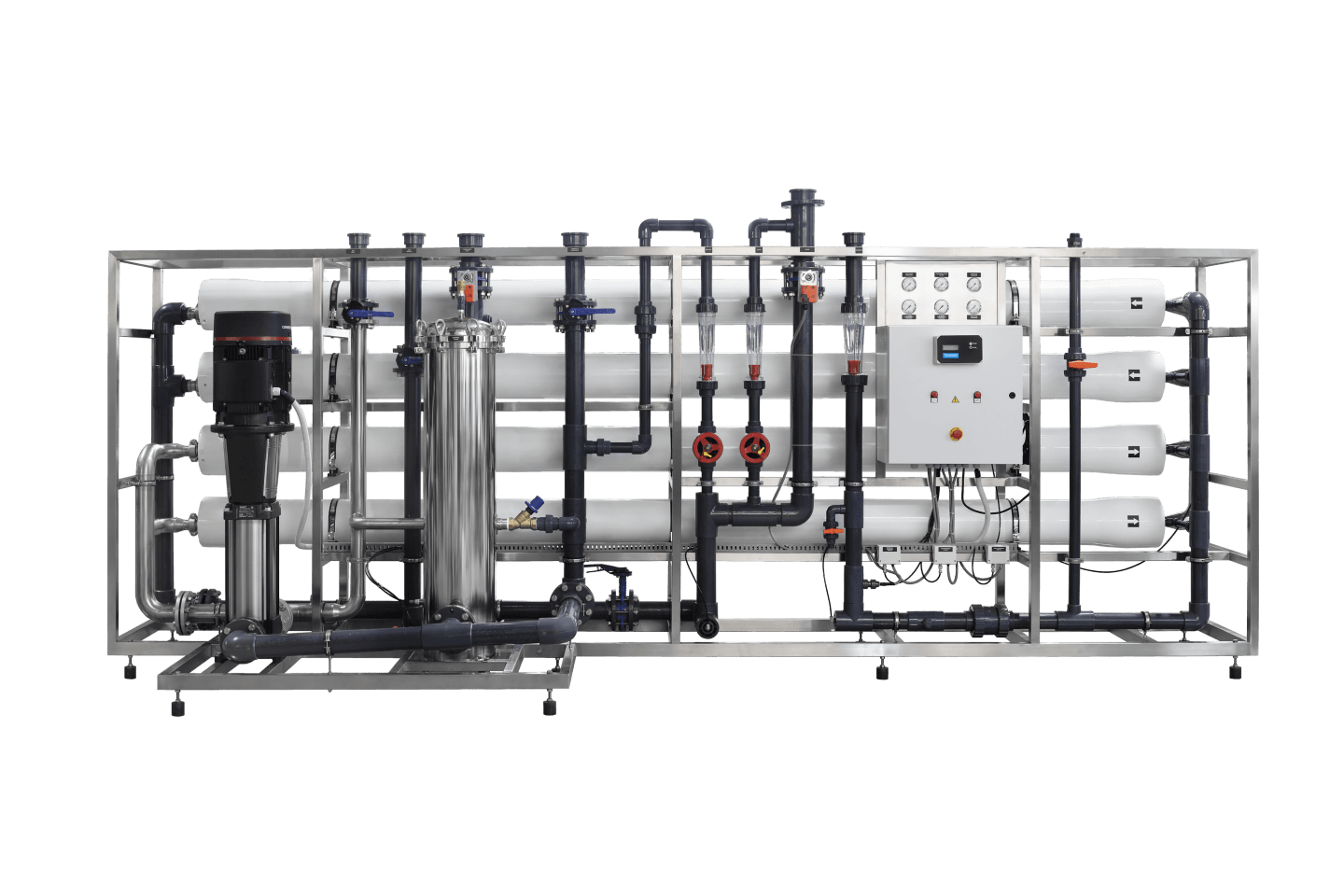

Industrial line units are offered in two variants.

PRO-MAX devices: with efficiencies from 2m3/h to 12m3/h are outfitted with rich serial equipment, the option to use a microcontroller with access to the web and process data collection in the cloud. Additionally, the devices from this series feature piping made out of stainless steel, suitable for high pressure.

PRO series devices, with efficiencies from 2m3/h to 56m3/h have the same advantages as series PRO-MAX, but feature plastic piping, which allows a more affordable price.

All units are equipped with a microcontroler, a high-pressure pump, an inlet filter, a permeate and concentrate rotameter(the PRO version also features a recirculate rotameter), a recirculate valve, electric, inlet and membrane flushing valves and an osmotic water level sensor. By utilizing an automatic controller and a full set of sensors, the setup boils down to connecting the water supply device, outputting the concentrate into a sewage system and connecting the purified water outlet to the tank where it will be stored, and installing a level sensor inside it, which will turn on the RO unit (the sensor is connected to the controller by default).

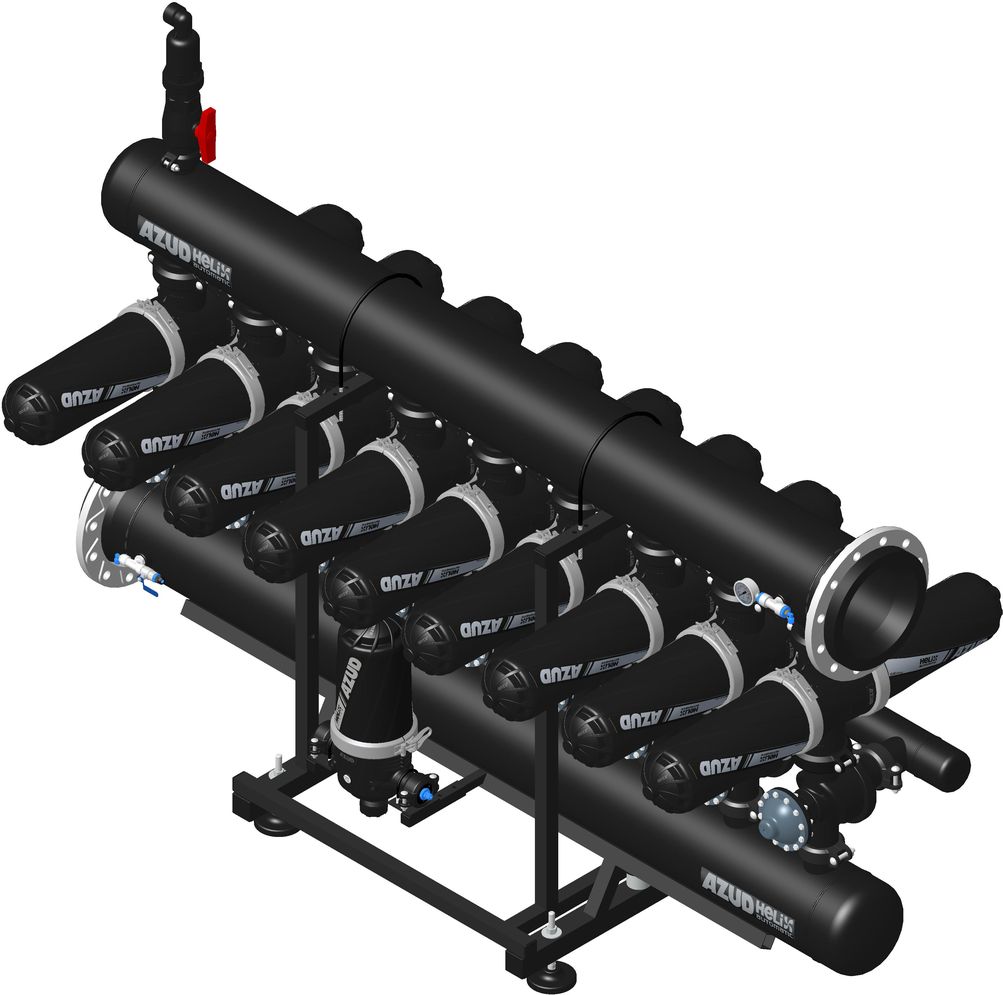

The delivery scope can be expanded with a permeate tank, with a distribution pump, an inonite softener or another kind of initial filter, an antiscalant or biocide dosage unit, a CIP unit (membrane digestion) and other components. If requested, MCC specialists will select apropriate equipment and prepare a technological schematic, and our service team will set up and launch the devices. We recommend getting to know other