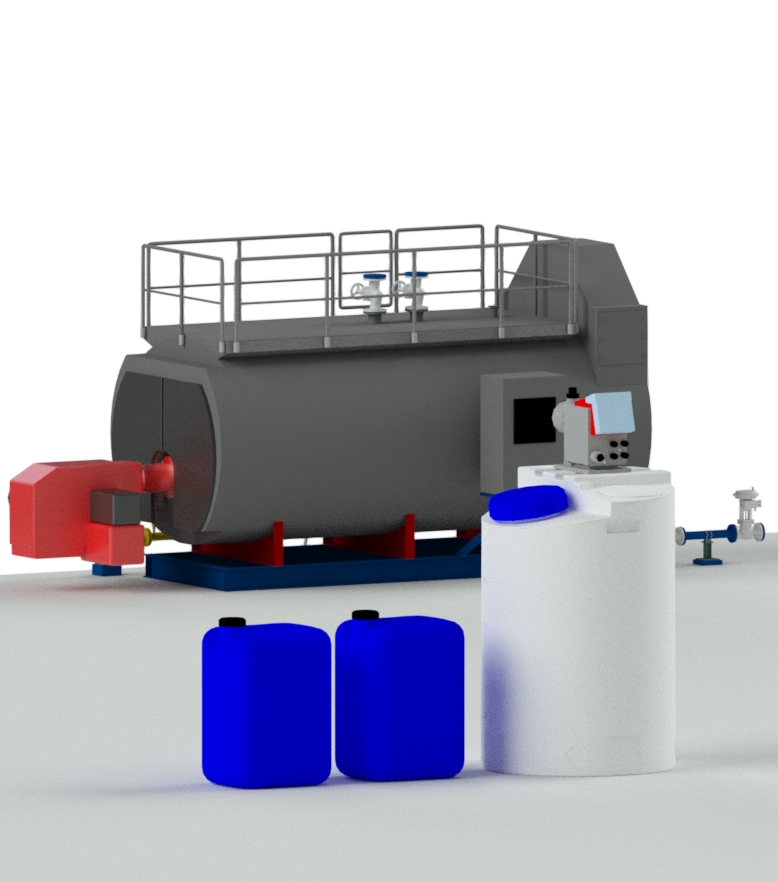

Description

Even relatively small steam boilers operate with temperatures surpassing 150°C, and pressure over 10 bar. In combination with the quick accumulation of salts contained in the supply water, boilers can be subject to many harmful phenomena, such as corrosion and sedimentation. The supply water is usually deprived of calcium and magnesium salts, but a malfunction in the water preparation system, breakthrough of the cooling water to the condensate, or even accumulation of residue hardness can, in conjunction with high pH and alkalinity, can lead to precipitation of sediments onto the heating surfaces.

This leads to a drop in efficiency of the boiler, energy losses, and in edge cases, overheating of materials and physical damage of the boiler. To prevent such occurences, use of apropriate chemical preparations is necessary. The preparations both stabilize the hardness, and keep the pH of the boiler water at the level of pH=11-12, reducing its corrosivity.

MCC offers selection and supply of the apropriate preparations, as well as specialized dosage systems. We also offer technological service, providing for an economical and safe exploitation of steam boilers.